The beam template is made from cheap plywood and a bit taller than the plans call for to increase the strngth of the beams. We drew a line perpendicular to the factory edge before cutting it out and then drilled holes along this line. This will allow using the big t-square to mark perpendicular lines on the good plywood and sight through the holes as a reference point later on to make sure the template is square so the beams all end up with the same amount of curve. To lay out the patterns I marked six lines on the plywood spaced so that there was a 1/2" margin between each piece to allow for cutting.

Then it's as easy as lining up the template with the line by sighting through the holes. This allows for much greater precision than just trying to line up the short edge by feel.

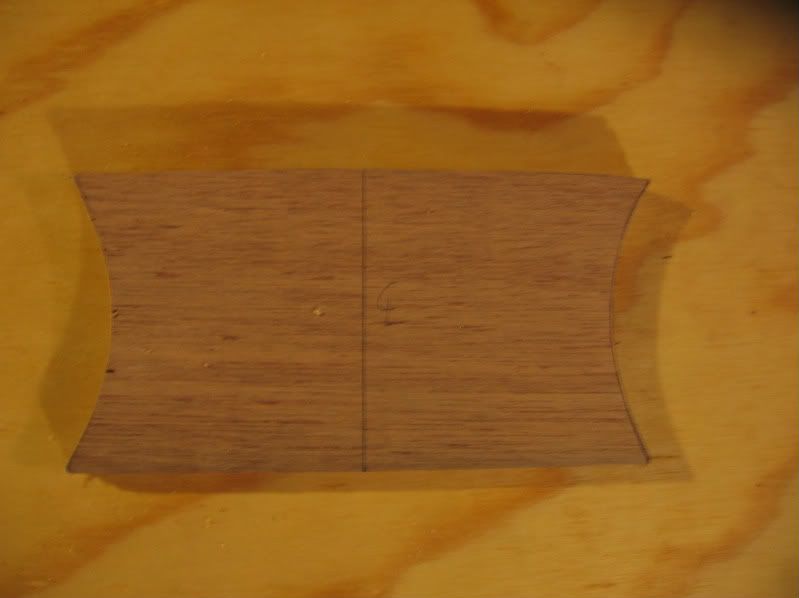

With all six beam halves traced the plywood got clamped to the new workbench and cut with the Japanese pull saw.

And then the edges planed down to the pencil line with a jack plane I picked up for $6 at a yard sale last year. I don't think there is any faster way to get to a piece of wood to your exact template than a hand plane.

Next come the butt blocks that join the two halves of each beam. These are also 1/2" plywood and curved to match the top of the beam.

So that's it for today. The center and aft beams are cut and shaped, the fore beam is waiting for longer clamps so I can safely cut it, and all three butt blocks are cut and shaped. The plan is for all three beams to get glued together tomorrow morning before the Super Bowl starts. Maybe now that we can lay out the plans and work at the same time we won't keep making so many mistakes!

No comments:

Post a Comment